Sharp internal and external bevelled edges and cornersĬut-outs can be done in multiple passes depending on the maximum cutting depth of the tool used and a positive or negative allowance can be specified to either 'under cut' or 'overcut' the shape if required.Profile around the outside / inside of open shapes.Advanced ramp options for controlling how the cutter enters the material, reducing heat build-up and cutter wear.

Lead in / out and overcut distance to prevent dwell marks appearing on components.3D tabs for smoother profiling plus advanced options for automatic positioning to hold parts in place when machining.Profile machining includes production cutting options that ensure parts can be held in place and accurately machined with high quality edges and corner detail.

Full control of cut direction is offered along with either automatic or manual control of tool entry point for each shape. The profiling automatically offsets for the tool radius and sorts nested shapes to ensure that inner shapes such as the center of a letter 'O' are cut before the outer shape (so parts are not released from the material before they are cut). Simply select the vector shapes you wish to profile, select the tool from the tool database and the software will do the rest.

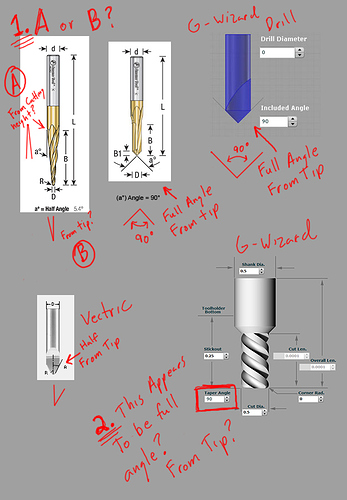

Education - Forum for Technicians and Engineers.Mill holder broke! Don't buy the harbor freight POS.Recommendations - Micro Mill to CNC Conversion - What mill should I start with.Newbie- Broke tool T1 - Need offsets remeasure.It broke off the cutting part of the bit, while the Shank stayed inside the collet. I think there are a few reasons why the break happened:ġ - the plywood was "bending" up a bit because it was being pulled by the bit, and that distorted movements in XY.Ģ - some of the settings didn't match the bit capabilities in terms of overloadĪny ideas to determine the reason for the bit breaking off? My Pocket Toolpath was a "Raster, Climb, Last", with all other settings default. This is part of a 2-toolpath file, but it broke off after a few seconds making a small hole. Material: 3mm plywood with 6mm wasteboard.

0 kommentar(er)

0 kommentar(er)